Products

Products

[Basic Knowledge about Cryopumps 1 ]

How does a cryopump work?

1.What is a cryopump?

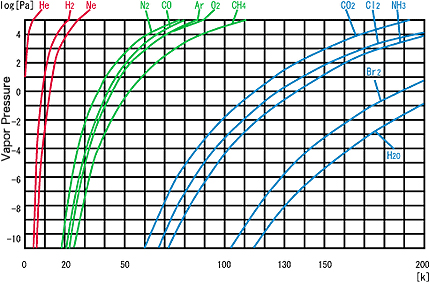

A cryopump is vacuum pump that traps gases and vapors by condensing them on a cold surface. For efficient evacuation under ultra-high vacuum, the vapor pressure for condensation, or the equilibrium pressure for adsorption must be less than 10-8Pa. Figure 1 shows vapor pressures of different gases. According to this figure, if the cryocooled surface such as cryo-surface and cryopanel is cooled below 20K, the vapor pressure of the gas becomes below 10-8Pa, provided the vapor pressure is lower than that of nitrogen. The lightest gases such as hydrogen, helium, and neon are not condensed at 20K, therefore instead of relying on condensation alone, adsorbent made of special porous materials are provided to adsorb them. By cooling down the adsorbent below 20K, those gases are adsorbed efficiently, and thereby a cryopump can achieve ultra-high vacuum.

There are two ways to “cryocool” the surface of the cryopump. One is a use of coolant such as liquid nitrogen(LN2, 77K) or liquid helium(LHe, 4.2K), and the other is a small closed cycle helium refrigerator.

Figure 1:Vapor Pressures of Different Gases

A compact, closed cycle helium refrigerator can perform a long period stable operation without refilling of coolant. Also it can achieve clean and ultra-high vacuum with simple and straightforward operation.

2.Basic Principle and Structure

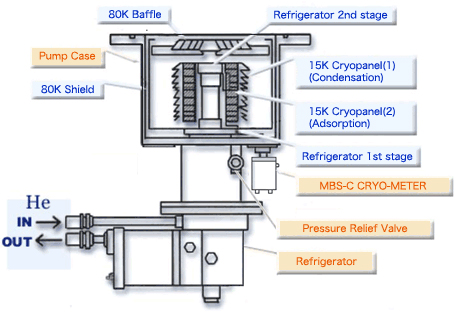

Let’s take a look at CRYO-U8H as an example. The refrigerator for CRYO-U cryopumps normally has two-stages. While the 1st stage has a large refrigerating capacity down to below 80K, the refrigerating capacity of the 2nd stage is small but cools down to 10 to 12K. Both 15K cryopanel(1) and 15K cryopanel(2) are mounted on the 2nd stage of the refrigerator, and shielded from the temperature radiation by the 80K shield and 80K baffle mounted on the 1st stage.

Figure2.CRYO-U8H

There are three types of gases pumped by cryopumps as follows.

| (1)Air(N2、O2) | :The residual gases after rough pumping the vacuum chamber. | ||

| (2)Outgas | 1 | H2O | :Adsorbed to the chamber wall.(The largest component in general vacuum system.)Major component of outgas from glass, plastic, and ceramic. |

| 2 | H2 | :Diffuses from inside of the metallic wall of the vacuum chamber.(Concerns in ultra-high or extreme high vacuum.)Outgas from high-temperature melted metal (especially Al) in deposition or sputtering process. | |

| 3 | CO、CO2、 CH4、CnHm |

:Fouling of the chamber wall. | |

| (3)Introduced Gas | 4 | Ar | :Sputtering Process |

| 5 | H2 | :Ion Implantation Process | |

| 6 | O2 | :Oxygenation | |

| 7 | Others | ||

As you see in Fig.1, the vapor pressure of water vapor becomes below 10-8 Pa at temperature of below 130K, and thus water vapor is pumped as a result of condensation on the 80K baffle and 80K shield. The next group of gases, nitrogen, oxygen, argon, and other gases of similar molecular weight are pumped at the exposed surface of 15K cryopanel(1) at the second stage, which is kept below 20K. The third group, mainly hydrogen, helium, and neon will not condense at 20K and will not be pumped efficiently by the metal surface because the equilibrium vapor pressure for cryosorption will be too high. To improve this situation, cryopumps have adsorbent of porous materials such as charcoal on the 2nd stage cryoarrays. The adsorbent is bonded to the inner surface of the 15K cryopanel(1) to prevent it from being covered with condensable gases.

Outside surface of 80K shield, 80K baffle, and 15K cryopanel(1) are specular finished in order to reflect radiant heat from room temperature. The inner surface of 80K shield is blackened to reduce the radiation heat transfer to the 15K cryopanel attached to the 2nd stage. In order that a cryopump to operate properly, both 80K shield and 80K baffle should be kept below 130K and 15K cryopanel to be kept below 20K.

In order to monitor those temperature, K(CA) thermocouple for 80K shield, and hydrogen vapor pressure gauge(H2VP) or CRYO METER MBS for 15K cryopanel are installed to the cryopumps.

(The standard for the electromotive force at 130K of K(CA) thermocouple is –5.5mV.)

3.Regeneration and Pressure Relief Valve

Cryopumps are not continuous throughout pumps such as oil diffusion pumps and turbo molecular pumps. As a cryopump keeps gases inside on 15K cryopanels by condensation and adsorption, it needs to be degassed and regenerated on a regular basis. During this regeneration process, the cryopump is warmed up, and condensed or adsorbed gases are turned into gas again. If large amount of gases are pumped, there is a risk of explosion. In order to prevent the explosion danger, all cryopumps feature a pressure relief valve.

The operating pressure of the pressure relief valve has been set at 20kPa(gage).

For safety reasons, DO NOT BLOCK the pressure relief valve, and DO NOT MODIFY it for other purposes. Also never use it as a purge valve in a regeneration process because refuse in purge gas may stick to the sheet of the pressure relief valve and may cause a leakage.

4.Cryopump System

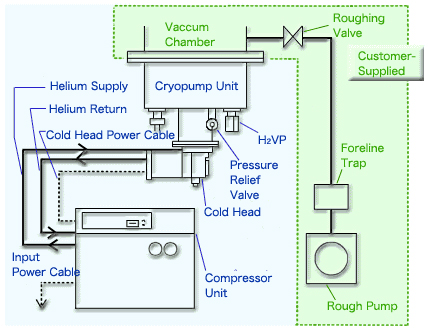

Cryopump system consists of

《1》Cryopump Unit(incl. Cold Head)

《2》Compressor Unit

《3》Flexible Hose(2)

The connection of the cryopump system is shown in Figure 3.

In addition, rough pump (customer-supplied) is necessary to operate and regenerate cryopumps. (Cryopumps cannot start from the atmospheric pressure.)

Figure3.Cryopump System